The RED team was privileged to join Vanderlande on a special mission to DHL Express Madrid’s (DHL) air hub at Barajas Adolfo Suarez Airport in Spain at the end of last year. We were there to see a robot that has been integrated into the parcel sorting process after taking part in a successful pilot project. The solution – known as Robot Auto Induct – is now fully operational at DHL, where it sorts flyers and packages of up to 2kg, providing a processing capacity of 1,500 units per hour with an accuracy of 99%.

It was impressive to watch the robot in operation, especially from an accuracy and speed perspective. Using a vision system that’s driven by AI, the robot can distinguish individual items and determine their size before feeding them into the sorting process. You can see the video and case study we produced here:

And after a gap of five years, we were also back at the state-of-the-art facility to see how Vanderlande’s parcel sortation system has increased capacity for the company’s services. We interviewed the key members of the DHL team as part of our client’s Fast Forward campaign and produced specific materials, which you can see via this link:

Many thanks as always to Diane from Vanderlande for her help and endless enthusiasm, as well as her colleagues Jesse and Pere. We also extend our appreciation to DHL’s Filip, Juan Carlos, Rafael and Jesus for their time and patience, making the project a fascinating and enjoyable experience.

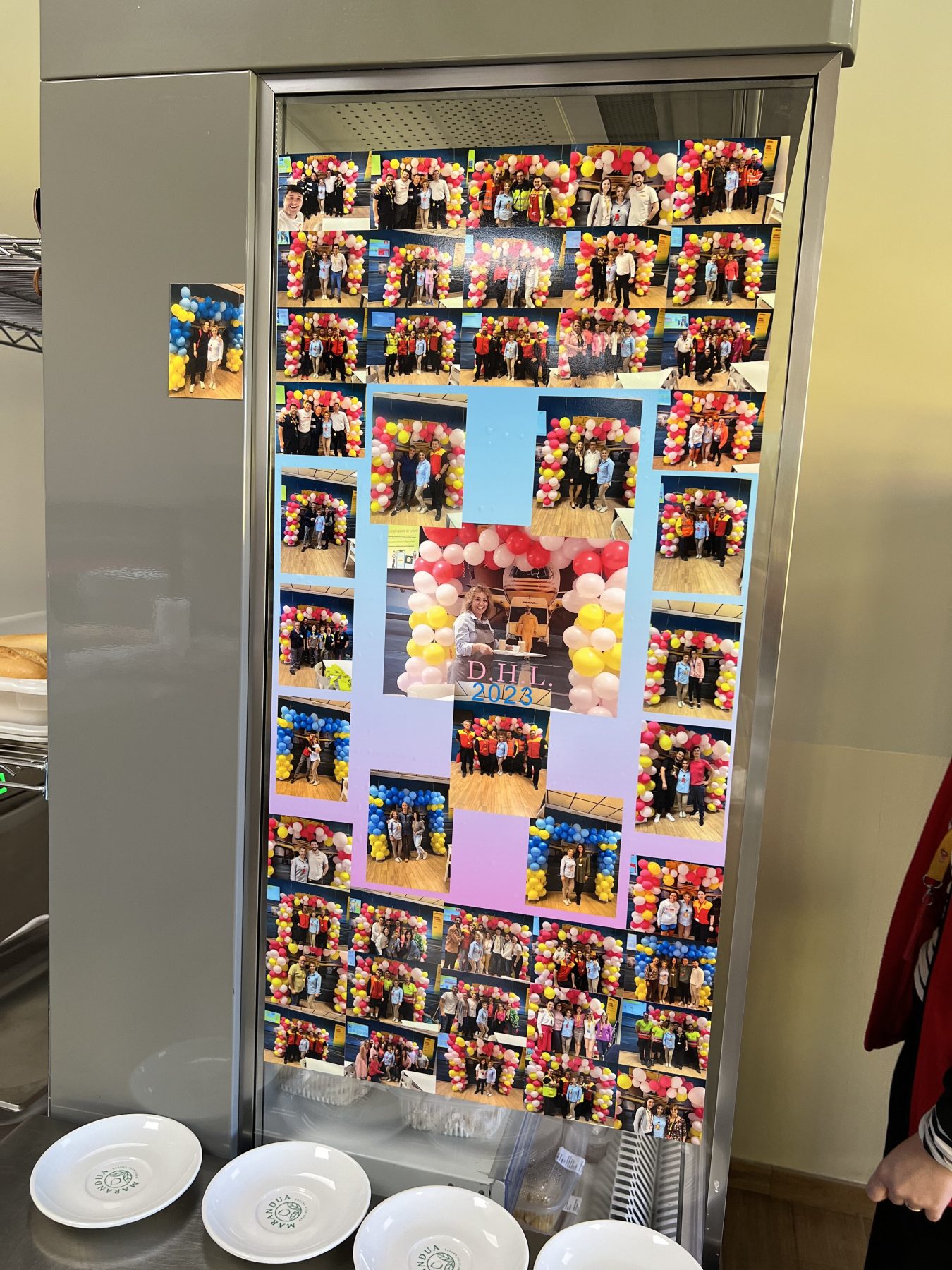

And finally, a special mention goes out to the lovely lady who looked after us so well at lunchtimes and arranged for a picture to be taken with us for her “hall of fame” in the DHL canteen.